NANOMIZER Inc.

Nanomization

The pulverization effects of Nanomizer can be divided into the ‘Surface Area Effect’ whereby surface area is increased and the ‘Size Effect’ whereby size is reduced.

While the ‘Surface Area Effect’ results in increased adhesive force and improvement in reaction efficiency, the ‘Size Effect’ results in greater transparency, more homogeneous mixing, less separation, easier absorption etc. It can therefore be applied in many fields.

Examples of the ‘Surface Area Effect’ and “Size Effect’ are briefly explained below.

■ Improvement in Ease of Consumption for Beverages that contain solids

such as soya milk

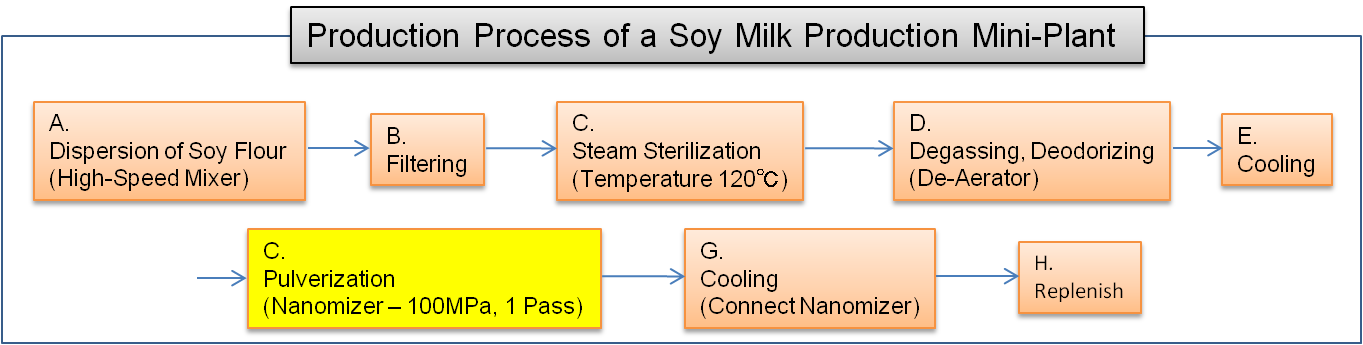

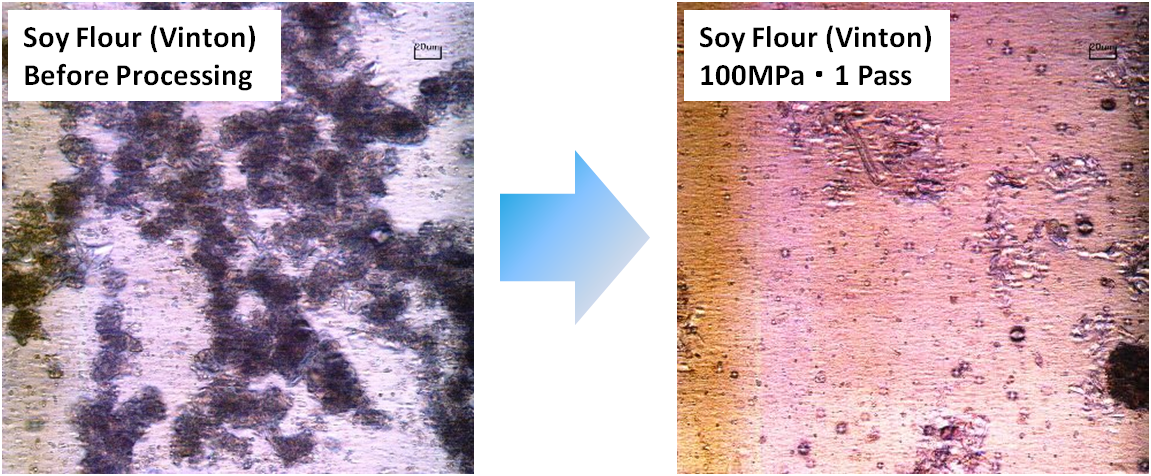

Generally, soy milk is made by separating and removing the okara after the crushed soya beans have been sufficiently immersed and components extracted. However, some soy milk does not remove the okara but pulverizes the soya beans and then disperse ten over percent of it in water instead. Since okara is high in nutrition, the latter method is actually preferred but due to the large particle size, this makes it very difficult to drink so the former method is generally used instead.

Using Nanomizer to process the soy milk, a delicious and low-cost beverage that includes all the okara can be produced. In addition, due to the excellent state of dispersion, a drastic improvement in stability in terms of separation can be expected. By being able to produce soy milk with a high concentration and low viscosity that has not been thought possible up till now, the product range can also be widened considerably.

![]()

Such technologies can be applied for other beverages

that contain solid particles such as vegetable juices.

■ Other Possibilities

【Improved adhesive and longer-lasting cosmetics such as foundation, lipstick etc 】

It is important for cosmetics like foundation and lipstick to be long-lasting without wearing off. Such

cosmetics are mainly composed of pigments and base materials. If such ingredients are made

smaller, the surface area increases and skin adhesion is therefore improved.

By using our Nanomizer for pulverization, it is possible to develop make-up products with vastly

improved adhesive and longer-lasting properties.

【Separation of Lecithin in Vegetable Oils】

Lecithin is included in the process of producing vegetable oils such as those made from soya beans.

Due to the effects of oxidation, the stability is negatively affected. Since lecithin is by itself a useful

by-product that can be used for pharmaceutical, cosmetics and food products, separating this from

the oil will not only improve the quality of the vegetable oil but also lead to the effective use of

lecithin. Using our Nanomizer to disperse fine water particles within the vegetable oil, the lecithin is

effectively hydrated with water. The lecithin can then be collected using centrifugal separation.

【Internal Coating in Beverage Cans】

PET (polyethylene terephthalate) resin of approximately 10 micrometer in thickness is applied onto

the inner wall of beverage cans to prevent direct contact of the beverage with the metal can

(aluminum, iron). The thickness must be thick enough to prevent pin holes but not too thick such

that there is a possibility that the paint peels off and mixes with the beverage when opening the

can. At the same time, a thinner coating will also reduce the paint cost. Using our Nanomizer

Technology, we have successfully developed one micrometer thick coating in collaboration with a

major can manufacturer that does not result in any pin holes. The demand for such coating is

expected to increase in future.