NANOMIZER Inc.

| C-Heavy Oil Emulsion Fuel |

C-Heavy Oil Emulsion Fuel

Emulsion fuel has long been considered as a way to reduce NOx in the shipping industry.

However, presently it has not achieved widespread usage because of reasons such as unstable combustion and deteriorating fuel efficiency while reducing NOx. On the other hand, while adding additives has been considered as a possible solution, this is not practical due to cost and space issues. By nanomizing the water particles in our Nano-Emulsion Fuel, we have managed to resolve these problems.

■ Advantages of C Heavy Oil Nano-Emulsion Fuel

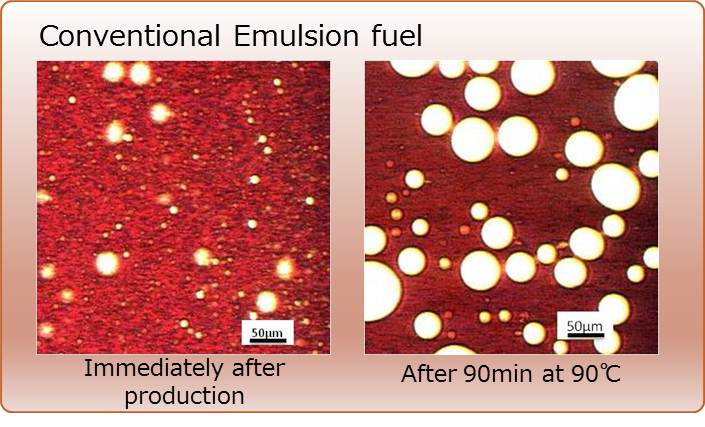

Compared to conventional emulsion fuel, the water particle size in nano-emulsion fuel remains extremely small even at high temperatures (90℃ 180 min) after it has been produced. Consequently, combustion is more stable and thus the reduction in fuel consumption and emission gases is higher.

![]()

Clear Advantage

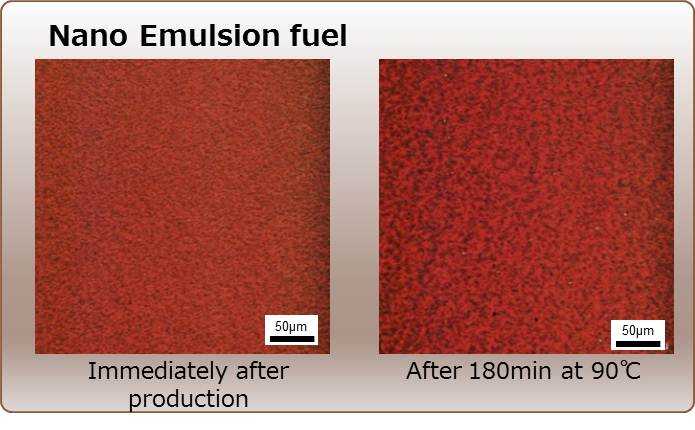

For conventional emulsion fuel, the oil and water are almost in a separated state

by the time it reaches the engine. As a result, the effects of emulsion fuel cannot be

exploited and the reduction in fuel consumption is not sufficient.

Our Nano-Emulsion Fuel is able to maintain a homogeneous emulsion even under high

temperatures and thus a more stable combustion and effect can be obtained.

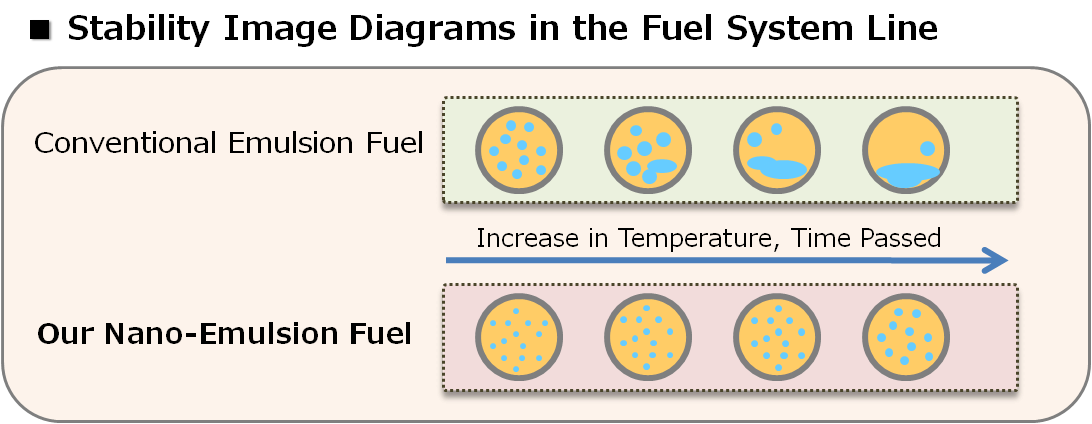

■ Problem with Returned Fuel

About 25-75% of the fuel that is supplied to the engine in a ship is returned to the mixing chamber without being burned. As the returned fuel has been heated to about 150℃, most of it would be in an almost separated state for conventional emulsion fuel.

Our Nano-Emulsion Fuel has a higher stability as the water particles have been reduced to a nano-level size. Moreover, our unique system ensures that there is no problem even when the returned fuel is supplied to the engine again.

Conventional emulsion fuel is extremely unstable under high temperatures.

![]()

The emulsion fuel supplied to the engine (large engines) is heated to about 150℃.

![]()

About 25-75% of the heated fuel with the oil and water in a separated state is returned to

the mixing chamber and then supplied to the engine again.

![]()

Effects of emulsion fuel not exploited due to unstable combustion.